Mt Bevan

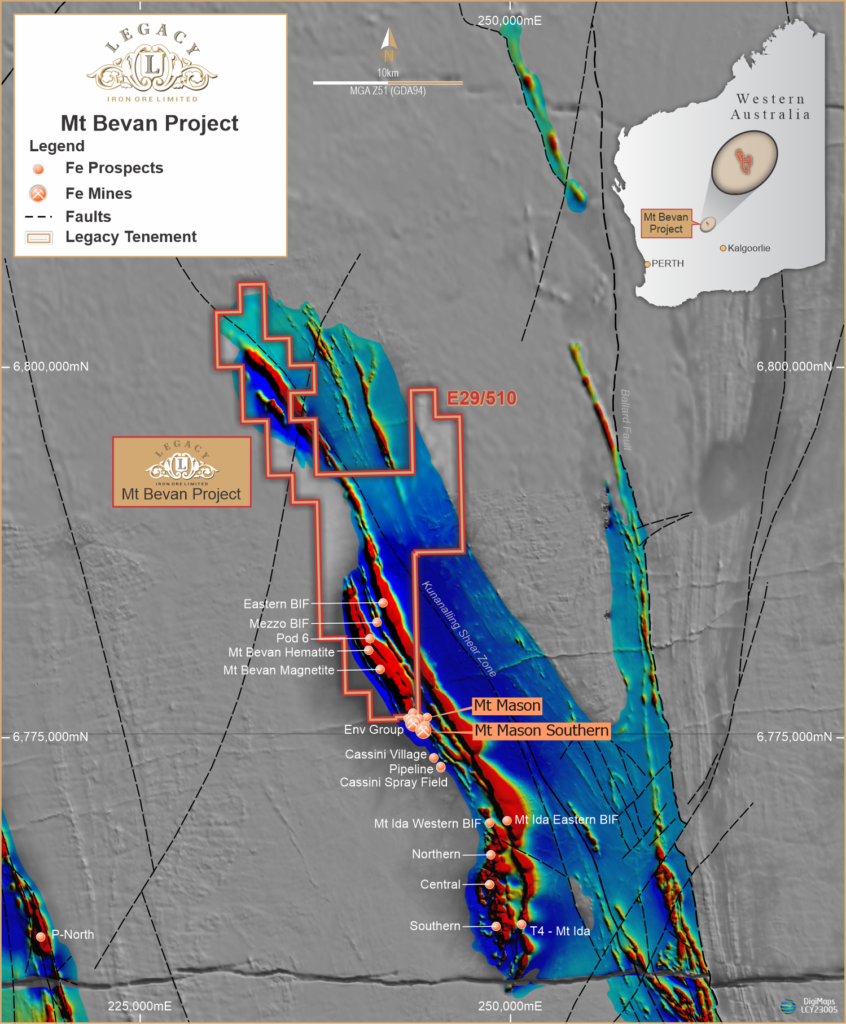

The Mt Bevan Project is the Company’s flagship project, comprising of a single tenement located approximately 100km west of Leonore in the Yilgarn region of Western Australia with close proximity to existing projects, road, rail and port facilities.

The project currently holds a substantial magnetite iron ore resource and is highly prospective for a number of base and critical metals.

Mt Bevan Magnetite

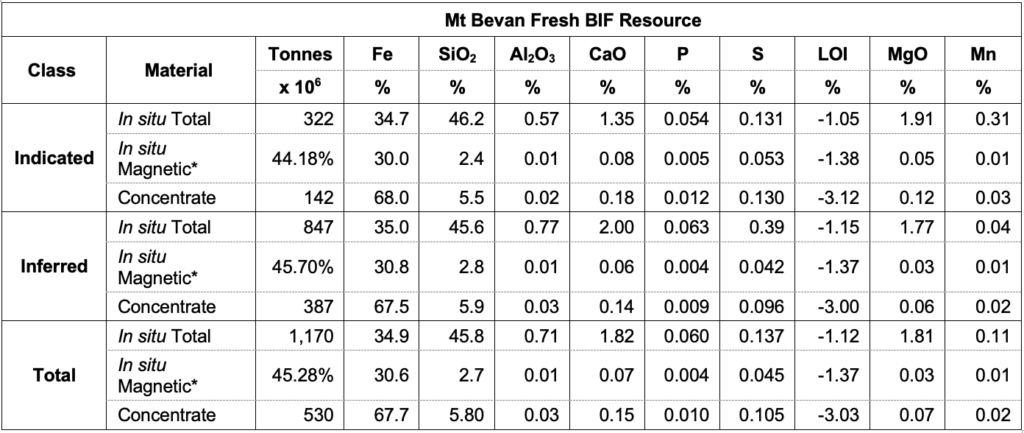

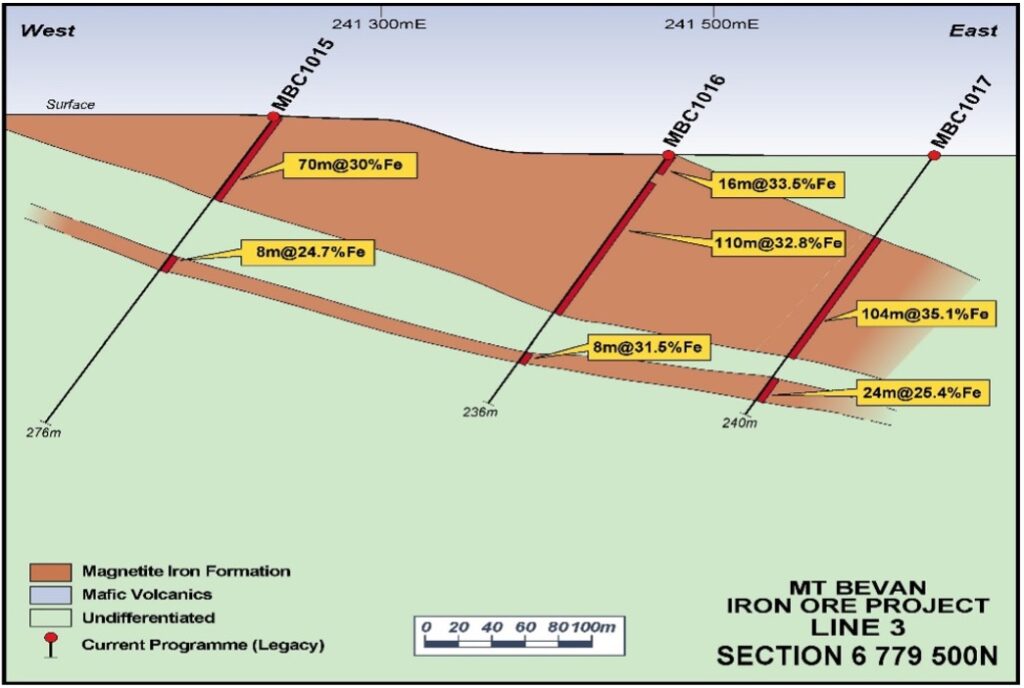

The Mt Bevan Magnetite project hosts 1,170 Mt of magnetite resource @ 34.9%. As announced on 15 November 2021, Hancock, through their subsidiary Hancock Magnetite Holdings Pty Ltd (HMPL) have the right to earn up to 51% of the project, and the current Joint Venture interests are as follows:

- Legacy – 42%

- Hawthorn – 28%

- Hancock – 30%

The existing resource only covers 2km section of the western BIF, with drilling and exploration work to be completed on the remaining 8km of strike. Hancock have appointed Atlas as Manager of the new Joint Venture, and are progressing towards an additional 21% interest through the delivery of a Pre-Feasibility Study (PFS).

Mt Bevan Lithium & Base Metals

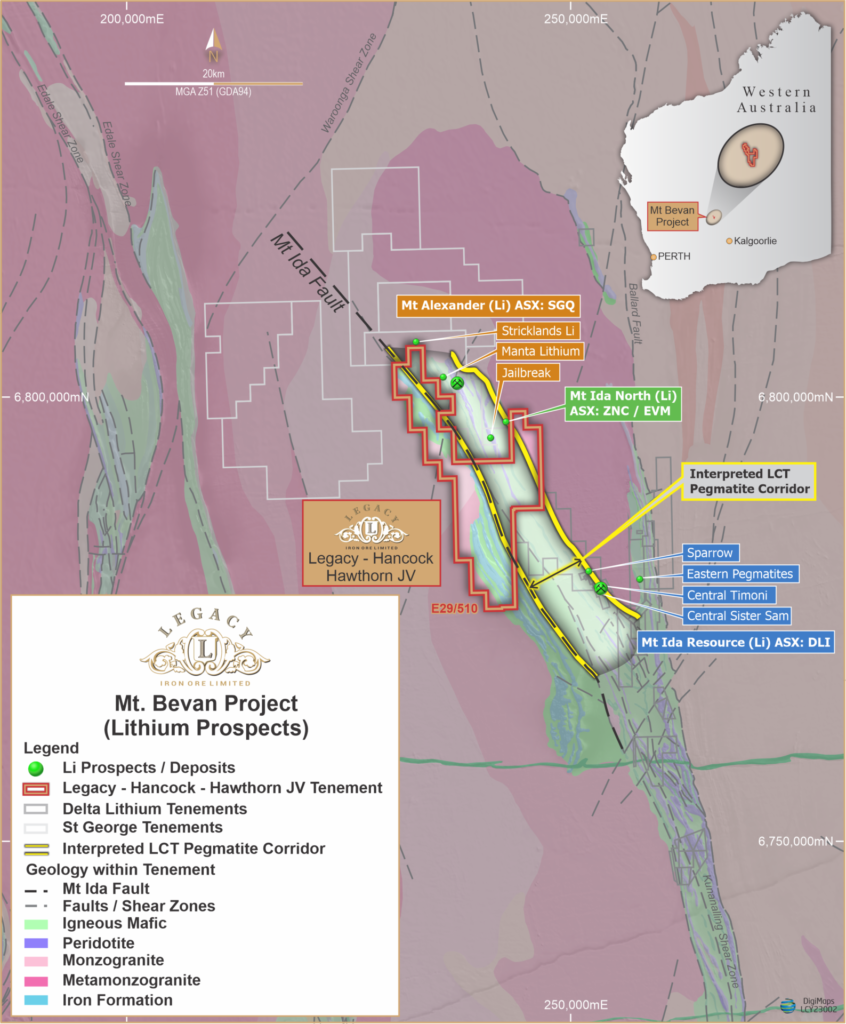

The Mt Bevan Project sits within a newly identified and emerging lithium province along the Mt Ida fault, with significant exploration success experienced by adjacent lithium explorers, Delta Lithium (ASX:DLI) and St George Mining Limited (ASX:SGQ).

As announced on 15 June 2023, Hancock have also entered into a binding Joint Venture agreement that outlined their earn-in rights with respect of lithium and other minerals and base metals. Under the terms of the agreement, Hancock may fund additional exploration and development activities up to $22 million for an additional 43.5% interest. The current Joint Venture interests are as follows:

- Legacy – 55.5%

- Hawthorn – 37%

- Hancock – 7.5%

Legacy retain the right to acquire up to 75 percent of the end product produced by any successful Joint Venture project, as the Company seeks to develop downstream mineral processing arrangements and assets.

The Project is also highly prospect for base metals, following an initial exploration program, the Company completed ground geophysics and auger geochemistry in the northernmost part of the tenement, delineating numerous early-stage nickel sulphide mineralisation targets for drill testing (refer to ASX announcement 30/04/2018).

Joint Venture Agreement with Hancock at Mt Bevan

Legacy Iron Ore Ltd ASX: LCY (Legacy Iron) and Hawthorn Resources Limited ASX: HAW (Hawthorn) are pleased to announce the execution of a binding joint venture agreement in respect of lithium and other minerals (Agreement) with Hancock Magnetite Holdings Pty Ltd (Hancock).

The Agreement formalises terms for Hancock to earn-in to all non-iron minerals, focusing on the exploration and development of lithium and other critical minerals at Mt Bevan (Project).